Applications of Composite Grating Panels.

This article will list the applications of composite grating panels in various fields, exploring why this breakthrough material is so popular and the superior values it brings compared to traditional materials. Composite grating panels, with their outstanding properties of durability, lightweight, and corrosion resistance, have become the preferred material in many different fields.

Enduring Strength in the Harsh Oil and Chemical Industry

In the harsh environment of the oil and chemical industry, where safety is paramount and corrosion is a constant threat, selecting the appropriate material plays a crucial role. Composite grating panels have proven their superiority, becoming the ideal solution to replace traditional materials like steel, which are prone to corrosion from chemicals and seawater. Their ability to withstand wet environments and exposure to various chemicals makes them the perfect choice for areas with strict safety and performance requirements. This is not just a matter of material durability, but also ensuring the safety of people and assets.

Work Platforms on Offshore Platforms and Processing Plants

One of the most common and important applications of composite grating panels in this industry is for flooring on offshore oil rigs and chemical processing plants on land.

Offshore rigs face the harsh marine environment, where salt and high humidity continuously attack metal structures. Traditional steel quickly rusts and weakens, requiring constant and expensive maintenance. Composite grating panels, made from fiberglass and composite resin, are completely immune to corrosion from seawater and most chemicals commonly found in the oil industry. This not only extends the floor's lifespan but also significantly reduces maintenance and repainting costs.

In chemical processing plants, floors and walkways are frequently exposed to acids, alkalis, and other solvents, which can severely damage traditional materials. Composite grating panels have excellent chemical resistance, maintaining their structural integrity even when exposed to strong corrosive substances. These panels not only ensure worker safety but also minimize the risk of slipping, which is crucial when working at height or in areas with slippery surfaces. The anti-slip textured surface of composite grating provides a secure grip even when the floor is covered with oil or chemicals, reducing workplace accidents—an extremely important factor in risky environments like oil refineries or fertilizer plants.

The good load-bearing capacity of composite grating panels is also a critical factor. While significantly lighter than steel, they can still support heavy equipment loads and high foot traffic. This allows for the design of lighter floor structures that are easier to install while still ensuring the necessary durability and safety for production operations.

Walkways, Staircases, and Chemical Handling Areas

In addition to the main flooring, composite grating panels are also widely used for walkways, staircases, and handrails on offshore rigs and in plants.

Walkways and staircases made from composite grating provide a stable, safe, and non-slip surface, especially in high-rise areas or places that are frequently wet. Their lightweight nature makes transportation and installation easier, particularly in hard-to-reach places or on floating structures like rigs. This helps save time and labor during construction and repairs.

In chemical handling areas, where chemical spills or vapors are likely, using composite grating panels is an effective safety measure. The corrosion-resistant material protects the structure from damage caused by chemical exposure. Moreover, the mesh structure of the grating allows chemicals or liquids to drain away quickly, preventing stagnation on the working surface, reducing worker exposure risk, and preventing dangerous puddles. This also makes cleaning and maintenance easier after chemical spills.

The electrical insulation properties of some composite grating panels are also a significant benefit in industrial environments with electrical presence. This material does not conduct electricity, reducing the risk of electrical shock for workers when working near electrical equipment or during electrical discharge incidents.

The Importance of Safety and Longevity in Investment

In the oil and chemical industry, the cost of downtime for maintenance or repairs is extremely high. Using composite grating panels, with their long lifespan and minimal maintenance requirements, helps significantly reduce downtime. This not only saves direct repair costs but also ensures continuous production operations, maximizing profits.

The UV resistance of composite grating panels is also an important factor, especially on offshore rigs or open-air plants, where materials are exposed directly to harsh sunlight. UV rays can degrade the strength of many traditional plastics, but composites are designed to resist this impact, ensuring the material does not become brittle, crack, or fade over time.

Investing in composite grating panels in the oil and chemical industry is not just a technical decision but also an important economic and strategic one. It is not simply a material replacement, but a solution to enhance operational safety, prolong the life of the facility, and optimize production efficiency in the most challenging working environments. The flexibility in design, lightweight, chemical and mechanical durability, and superior safety features make composite grating an indispensable choice for new projects and upgrades in this field.

Contributing to the Sustainability of Transportation and Infrastructure

The transportation industry is the backbone of the economy, requiring infrastructure structures to have high durability, good load-bearing capacity, and resistance to harsh environmental conditions, from temperature fluctuations and humidity to salt exposure (especially in coastal areas or places using de-icing salts). Composite grating panels have opened up a new direction for building and renovating transportation projects, offering many superior benefits compared to traditional materials like concrete or steel. They are used to create walkways and roadways due to their good load-bearing capacity and high durability. Their applications not only enhance the lifespan of the structures but also significantly improve construction and maintenance efficiency.

In the road sector, composite grating panels are used for bridge decks, pedestrian walkways on bridges, roadside drainage gutters, and even supporting structures for road surfaces.

When used as bridge decking, composite grating panels are especially effective on bridges that need to reduce their self-weight or in areas that are frequently exposed to wetness or salt. The lightweight nature of this material helps reduce the load on the foundation and bridge pillars, allowing for the design of lighter, simpler structures, thus reducing overall construction costs. At the same time, its corrosion resistance protects the structure from damage caused by rainwater, salt, and pollutants from vehicles.

Pedestrian walkways made from composite grating panels provide a safe, non-slip surface and allow rainwater to flow easily through the gaps, preventing water buildup that could be dangerous for pedestrians. For railway projects, composite grating can be used as decking for short railway bridges or maintenance areas, where durable, lightweight, and corrosion-resistant materials are needed. Its natural electrical insulation properties are also beneficial in the railway environment, reducing risks related to leakage current.

Additionally, composite grating panels are used as drainage gutter covers along roadways. The mesh structure allows water to drain quickly, preventing road flooding, while being durable enough to withstand vehicle traffic. Using corrosion-resistant materials like composites for drainage systems is especially important in coastal areas or places with highly corrosive environments, helping extend the lifespan of the drainage system.

Manhole Covers, Fences, and Auxiliary Structures

Some projects even use composite grating panels as manhole covers, making repairs and maintenance easy without having to replace the entire structure. Composite manhole covers are significantly lighter than cast iron or concrete, allowing workers to lift them easily to inspect or maintain drainage systems, underground cables, or other underground structures. This not only improves work efficiency but also reduces the risk of worker injury.

The corrosion resistance and durability of composites also make composite manhole covers the ideal choice for areas prone to corrosion, such as coastal areas or chemical plants. Unlike cast iron covers that are prone to rusting and degradation, composite covers maintain their integrity and aesthetics over time. Moreover, composite manhole covers do not have high scrap value like metals, helping reduce the issue of manhole cover theft, a common safety concern in many places.

Composite grating panels can also be used as barriers on construction sites, temporary floors for workers, or other auxiliary structures during the construction and maintenance of transportation infrastructure. The flexibility in fabrication allows the creation of different shapes and sizes to meet the specific requirements of each project. Using composite grating not only saves costs but also shortens construction time. Its lightweight and easy installation help accelerate transportation projects, minimizing traffic disruption and impacts on local residents.

Applying composite grating panels in the transportation sector brings significant economic and environmental benefits. From an economic perspective, the low maintenance cost and high durability of this material help reduce the total cost of ownership over its lifetime. Although the initial cost may be slightly higher than traditional materials, the savings from reduced maintenance, repairs, and minimal downtime quickly offset this difference.

The lightweight nature of composite grating also helps reduce transportation and installation costs. Fewer workers and lifting equipment are needed to move and install composite grating panels compared to steel or concrete, especially in large or complex projects. This not only saves labor costs but also minimizes the environmental impact from transportation and energy use.

From an environmental standpoint, using composite grating panels can be seen as a step towards greater sustainability. The composite manufacturing process typically consumes less energy than steel or concrete production. Furthermore, due to their high durability and corrosion resistance, structures using composite grating need to be replaced less frequently, reducing construction waste. Some types of composite are even recyclable, or at least less harmful when discarded compared to materials that corrode and release chemicals. Improving drainage and reducing waste accumulation on streets also contributes to maintaining a cleaner environment. Overall, choosing composite grating for transportation projects not only brings technical and economic benefits but also demonstrates a commitment to sustainable, environmentally-friendly construction solutions.

Breakthrough in Modern Construction and Diverse Applications

The construction industry is always seeking new materials that can improve performance, reduce costs, and enhance safety for structures. In the construction industry, composite grating panels are a breakthrough material, used for floors, stairways, and other supporting structures. With their corrosion resistance and ability to withstand weather elements, composite grating panels ensure that building structures remain in the best condition without frequent maintenance. The flexibility in design and construction of this material has opened up many application possibilities in civil, industrial, and commercial construction.

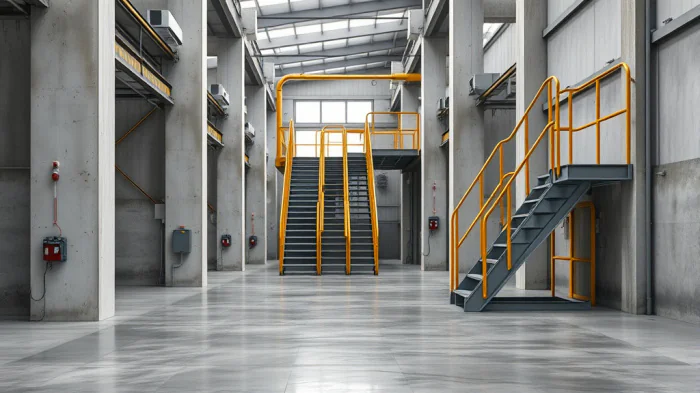

Floors, Walkways, and Staircases in Construction Projects

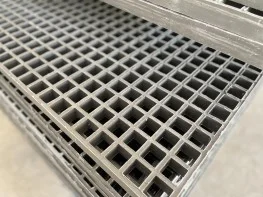

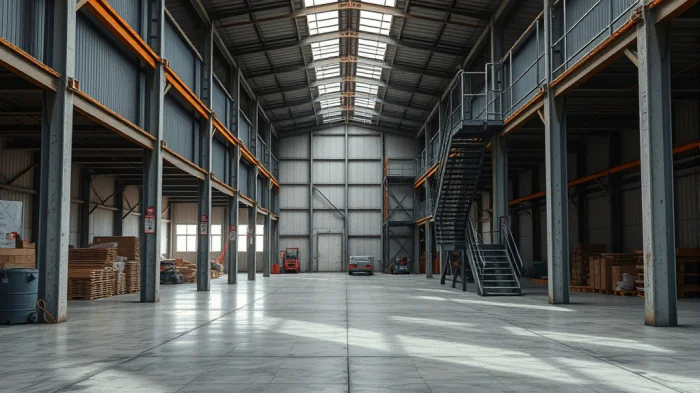

Composite grating panels are widely used to create floors in areas requiring high durability, good drainage, and corrosion resistance.

The most common application is for industrial plants, production workshops, warehouses, and water treatment plants. In these environments, floors are frequently exposed to chemicals, oils, water, or other corrosive substances. Concrete floors may corrode or crack, while steel floors are prone to rusting. Composite grating panels provide the ideal solution due to their excellent resistance to chemicals and corrosion, ensuring floors remain clean, safe, and durable over time. The mesh structure also allows liquids to drain quickly, reducing the risk of slips and providing a safer work environment.

Walkways and staircases made from composite grating are also a popular choice in construction projects, especially for access to storage tanks, elevated work platforms, or outdoor emergency stairways. Their lightweight nature makes installation easier in difficult-to-reach locations. The anti-slip surface ensures safety even when it’s raining or the surface is wet. Their UV resistance and ability to withstand changes in temperature and humidity ensure these structures maintain durability and aesthetics without needing paint or regular maintenance. This not only increases the lifespan of the structure but also creates a safer work environment for workers.

In civil and commercial projects like parking lots, walkways around swimming pools, or rooftops, composite grating panels are also beginning to be used. They provide a modern appearance, efficient water drainage, and durability in harsh weather conditions. For parking lots, the grating’s hollow structure allows dirt and water to drain, keeping the surface clean. For pool areas, the grating walkway not only prevents slips but also allows water to drain away easily.

Supporting Structures and Technical Floors

Besides being used as floors and walkways, composite grating panels are also used as parts of supporting structures or technical flooring systems.

They can be used for flooring in electrical cable systems or piping in technical basements or overhead. Their excellent load distribution and corrosion-resistant properties help protect cable and pipe systems from environmental damage. The mesh structure also allows easy access for inspection, repair, and maintenance of the systems beneath. Their lightweight nature reduces the load on the main building structure.

Composite grating panels are also used as covers for technical channels or drainage gutters in factories or residential areas. Compared to heavy concrete panels, composite panels are significantly lighter and easier to lift for cleaning or repairs underneath. Their ability to withstand vehicle traffic (depending on type) and resist corrosion makes them a durable and convenient option.

In specialized applications such as clean rooms or laboratories, composite grating can be used for raised floors or underfloor ventilation systems. This material does not generate dust, is easy to clean, and is resistant to chemicals, meeting strict hygiene and safety requirements in these specialized environments.

Construction Efficiency and Long-Term Benefits

Using composite grating panels brings significant efficiency to the construction process. Their lightweight nature reduces transportation costs to the construction site. Installation is also faster and simpler compared to pouring concrete or welding steel. The panels are often pre-cut to required sizes at the factory or can be easily cut on-site using regular tools, reducing time and labor on-site. No need for complex rust-proof coatings or surface protection measures.

The long-term benefits of using composite grating panels in construction are clear. Maintenance requirements are nearly zero, except for regular cleaning. Their high durability in all weather conditions and corrosive environments ensures the structure stays in optimal condition for decades. This not only saves on costly regular maintenance but also eliminates operational disruptions caused by repair work.

Fire resistance in some types of composite grating (with fire-retardant additives) is also an important safety factor, especially in industrial and public applications. This material does not sustain flames and produces less toxic smoke when burned compared to traditional plastics. The combination of durability, safety, economic efficiency, and environmental benefits has established composite grating as an advanced construction material that is indispensable in many modern types of buildings.

Expanding Reach into the Seafood Industry and Other Specialized Fields

The unique properties of composite grating panels are not confined to traditional industries. They have also found groundbreaking applications in specialized fields, where specific environmental or functional requirements demand a flexible and durable material. Particularly in the seafood industry, composite grating panels are used to create aquaculture platforms and wastewater treatment areas. In addition to the main applications mentioned, composite grating panels are also used in industries like electrical power, medical device manufacturing, and even in aerospace.

Applications in the Seafood Industry and Water Treatment

In aquaculture, maintaining a clean and stable water environment is key. Composite grating panels have become the ideal choice for building structures in both saline and freshwater environments.

They are used to create flooring for coastal aquaculture areas, walkways on floating platforms, and flooring for seafood processing or storage areas. With their good drainage capabilities and waterproof features, composite grating panels help maintain the required moisture for aquaculture species while minimizing waste buildup. The mesh structure allows water to flow easily, improving the efficiency of water filtration and treatment systems. This is particularly important in high-density ponds or tanks, where continuous water circulation is needed to ensure oxygenation and waste removal.

The corrosion resistance of composite grating panels is a major advantage in saline environments, where metal structures quickly rust. Composite grating does not weaken or degrade due to salt, helping aquaculture platforms last longer and remain safe for workers. The non-slip surface also provides the necessary safety when working in the constantly wet environment.

In wastewater treatment systems, composite grating panels are widely used as work platforms, trench covers, or support structures for filtration equipment. Wastewater treatment environments often contain corrosive chemicals and microorganisms that can harm traditional materials. Composite grating resists these chemicals, without degrading or corroding. The mesh structure allows water and sludge to drain away, keeping the working surface clean and safe. This is a perfect example of how this material can improve production processes and product quality. Using composite grating helps reduce maintenance requirements in harsh working environments, optimizing the operational efficiency of wastewater treatment plants.

The power industry and thermal, hydroelectric power plants are also places where composite grating panels shine.

They are used as work platforms in areas with power generators, substations, or areas containing chemicals (such as acid in batteries). The electrical insulation properties of composite grating are an important advantage, protecting workers from electric shock risks when working near high-voltage equipment. At the same time, its corrosion resistance and high mechanical strength ensure safety and longevity for floor structures in industrial environments.

In medical device manufacturing, where hygiene and chemical resistance are paramount, composite grating also finds its place. Although not as common as materials specifically designed for clean rooms, composite grating can be used in auxiliary areas, chemical storage floors, or walkways in areas that do not require absolute sterility but still need easy-to-clean, non-slip, and chemical-resistant surfaces.

Even in the aerospace industry, though on a smaller scale and in very specialized applications, composite materials have been the foundation for many ultra-light and durable structures. Composite grating panels, as a type of composite material, may be considered for auxiliary applications on the ground or in experimental structures where lightweight, durability, and environmental resistance are required. The use of grating panels in these fields demonstrates that they are not only a popular material but also provide added value for all industries.

Exceptional Potential and Flexibility

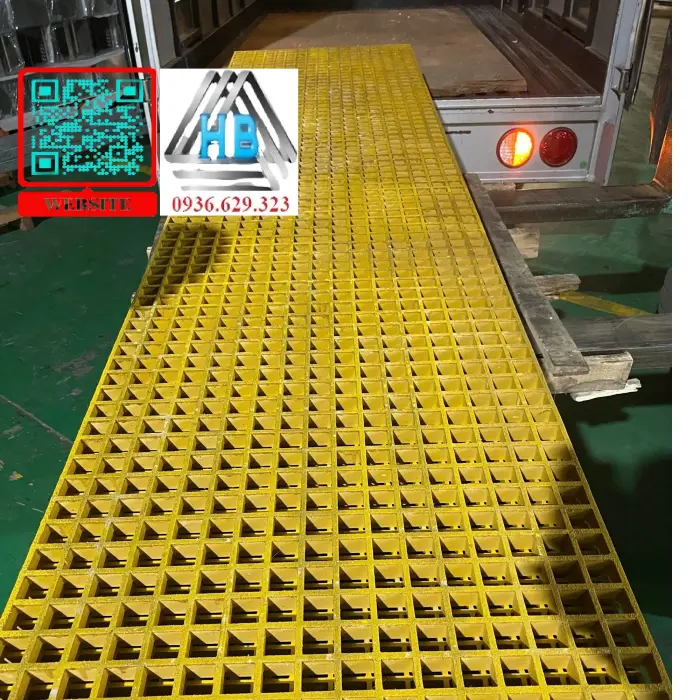

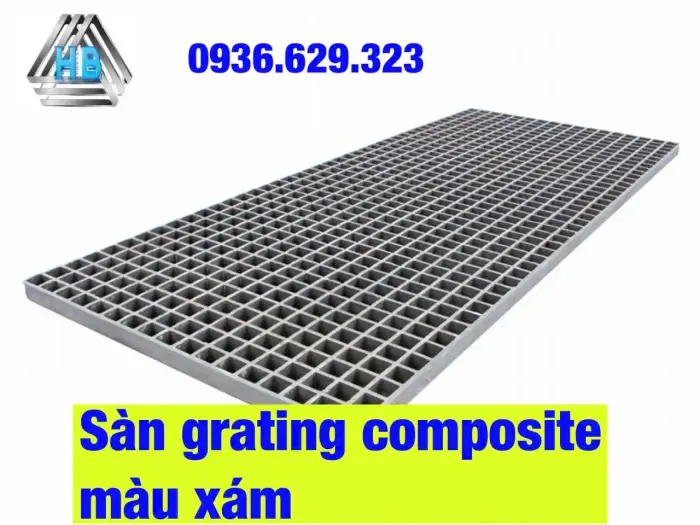

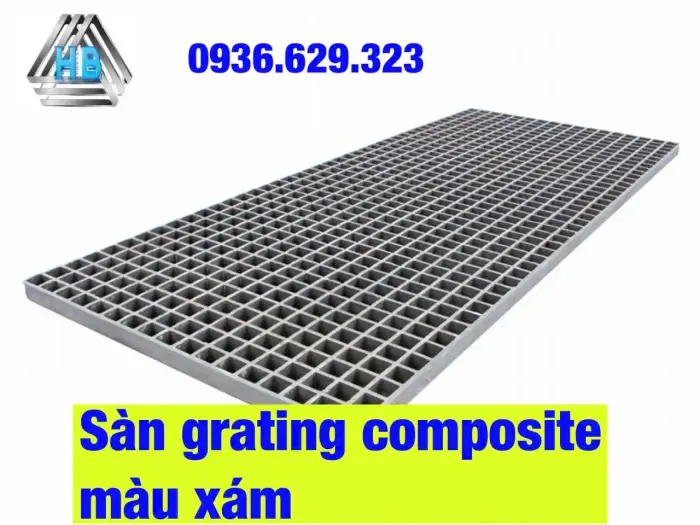

The diversity of application fields demonstrates the vast potential of composite grating panels. With high customization capabilities in terms of size, color, resin type (polyester, vinyl ester, phenolic...), and reinforcement fibers (fiberglass, carbon fiber), composite grating can be designed to meet the specific technical requirements of each industry.

For example, phenolic composite grating has excellent fire and smoke resistance, making it ideal for applications in subway tunnels or on ships, where fire safety is strictly regulated. Vinyl ester grating offers stronger chemical corrosion resistance, suitable for specialized chemical manufacturing plants.

The ability to combine features such as lightweight, high strength, corrosion resistance, electrical insulation, anti-slip, fire resistance, and easy installation makes composite grating an attractive alternative to traditional materials in many different situations. From the diverse applications of composite grating panels, it’s clear that this material is not just an alternative to traditional materials but also opens up new opportunities in design and construction, while enhancing safety and sustainability standards across industries. The continuous development of composite technology promises even more innovative applications for composite grating panels in the future.

Conclusion

In conclusion, composite grating panels have established themselves as a versatile and effective material, with widespread applications across various industries. From harsh environments like oil and chemicals, where superior corrosion resistance and safety are required, to transportation and construction, where they contribute to sustainability and construction efficiency, and even in specialized fields like aquaculture and electrical power, composite grating panels provide undeniable value. The combination of features like lightweight, durability, corrosion resistance, non-slip properties, electrical insulation, and easy installation has transformed them from a material alternative into an optimal solution, improving operational efficiency, ensuring safety, and contributing to the sustainable development of industries in the new era.

HOA BINH CONSTRUCTION TECHNOLOGY MANUFACTURING & TRADING CO., LTD

Specializing in manufacturing composite grating panels - composite manhole covers - composite trash grilles nationwide.

- Address: 69 Tan Lap, Tan Lap Ward, Dong Hoa, Di An City, Binh Duong, Vietnam

- Main manufacturing plant: 68 Tan Hien Street, Thien Tan Commune, Vinh Cuu District, Dong Nai

- 3rd Manufacturing Plant: Sao Vang Industrial Complex – Tho Xuan District – Thanh Hoa

- Hotline: 0936629323 - 0916206646 - (028)38755709

- Email: phongkd@xaydunghoabinh.com.vn