Common Places for Using Composite Grating Panels - A Sustainable Solution for Modern Industries.

Main Sectors Using Composite Grating Panels – Versatility and Flexibility in Practice

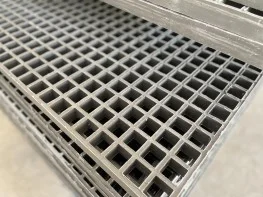

In the development of the industrial sector, choosing the right material plays a decisive role in durability, safety, and construction costs. Composite grating panels have demonstrated high adaptability and bring outstanding benefits in various specific fields. Below are some typical industries that highlight the key features of this material.

This section will address the reasons why composite grating panels have become an essential material in these sectors, while also analyzing their applications from both a technical and economic perspective. Each industry has its own specific requirements, and composite grating panels meet these standards effectively, helping to enhance work efficiency, minimize risks, and extend the lifespan of projects.

Oil & Gas and Chemical Industry – Safe Work Platforms in Harsh Environments

The Importance of Load-Bearing and Corrosion-Resistant Floors in the Oil & Gas Industry

In the oil & gas industry, work areas are frequently exposed to chemicals, high temperatures, and high pressure, requiring construction materials that are highly resistant and environmentally safe. Composite grating panels are the optimal solution for flooring in oil rigs, processing plants, and facilities housing hazardous chemicals.

Unlike traditional materials, composite grating panels have superior corrosion resistance, ensuring long-lasting durability and reducing maintenance costs. Additionally, their anti-slip properties give workers peace of mind when working on surfaces, reducing occupational accidents. Notably, the lightweight nature of composite grating helps reduce structural load, saving on transportation and installation costs.

Specific Applications in the Oil & Gas Industrial Sector

Oil & gas plants typically use composite grating panels for flooring in areas such as processing plants, wastewater treatment systems, or control rooms where high safety and hygiene standards are required. These floors are not only easy to clean but also prevent dust accumulation, helping to maintain a clean working environment.

Furthermore, in maintenance activities, composite grating panels are highly flexible, easy to disassemble and replace, helping to reduce operation time and costs. With their resistance to chemical agents and harsh climates, this material has proven to be perfectly suitable for oil & gas industry applications.

Transportation Industry – Providing Convenience and Durability for Bridge and Road Projects

The Role of Composite Grating Panels in Bridge and Road Construction

In the transportation industry, particularly in the construction of bridges, tunnels, drainage systems, or manhole covers, composite grating panels have made a technological breakthrough. With excellent load-bearing capacity, resistance to vibrations, and immunity to weather-related corrosion, this material ensures that structures remain strong and durable over time.

Instead of using traditional materials such as cast iron, steel, or concrete, composite grating panels help reduce the overall weight of the structure, making assembly, transportation, and maintenance easier. This is especially important in large-scale projects where construction time and costs are crucial factors.

Benefits in Bridge Systems and Manhole Covers

Bridge projects, manhole covers, and pedestrian walkways all require high durability, anti-slip features, and the ability to bear heavy loads. Composite grating panels meet all these criteria, while also helping to reduce the risk of accidents for both traffic participants and maintenance workers.

Moreover, the flexibility of the material allows engineers to easily design extensions, upgrades, or replacements without affecting the overall structure. For this reason, composite grating panels are increasingly becoming the new trend in modern transportation infrastructure projects.

Construction Industry – Creative Materials for Sustainable Structures

Flooring, Staircases, and Other Support Structures

In construction, composite grating panels have made a significant mark by replacing traditional materials like steel or concrete in many applications. Used for factory floors, rooftops, staircases, and retaining walls, this material provides safety, durability, and is particularly less affected by weather conditions.

Corrosion resistance and high load-bearing capacity ensure that the structures retain their appearance and functionality over time, reducing the need for regular maintenance. Additionally, the fireproof and anti-slip features create a safe working environment, helping to increase workforce productivity.

Improving Project Quality with Highly Practical Materials

Composite materials not only help diversify architectural styles but also open up creative opportunities in design. Architects can take advantage of the flexibility of composite grating panels to create unique, environmentally-friendly, and technically advanced structures. This is why composite grating panels are becoming increasingly popular in high-end building projects, shopping centers, and public works.

Aquaculture – The Optimal Solution for Aquaculture and Wastewater Treatment

Applications in Aquaculture Platforms and Water Treatment Systems

In the aquaculture industry, maintaining humidity, ventilation, and cleanliness is always a major challenge. Composite grating panels are the ideal material for designing aquaculture platforms, fish tanks, or wastewater treatment areas due to their quick water drainage, excellent waterproofing, and non-polluting characteristics.

They help maintain an ideal living environment for aquatic species, minimize the accumulation of organic waste, and reduce bacterial or parasitic diseases. Additionally, the panels are easy to clean, inspect, or maintain, contributing to improved production efficiency.

Positive Impact on Aquaculture Production Processes

The use of composite grating panels also helps reduce cleaning time, save operational costs, and create a clean and safe environment for both farmers and the aquatic species. Furthermore, their corrosion resistance ensures that the material retains its original properties after years of use, meeting the stringent requirements of modern aquaculture.

Conclusion

The places where composite grating panels are commonly used are diverse, ranging from heavy industries to construction, transportation, aquaculture, and many specialized fields. These panels are the ideal material solution that enhances performance, ensures safety, and promotes sustainability in long-term projects. Not only are they an effective alternative to traditional materials, but composite grating panels also open up many opportunities for creativity and innovation in technical and architectural design, helping to drive the development of modern industries today.

HOA BÌNH CONSTRUCTION TECHNOLOGY MANUFACTURING & TRADING CO., LTD

Specializing in manufacturing Composite Grating Panels - Composite Manhole Covers - Composite Trash Barriers nationwide.

- Address: 69 Tan Lap, Tan Lap Ward, Dong Hoa, Di An City, Binh Duong, Vietnam

- Main manufacturing plant: 68 Tan Hien Street, Thien Tan Commune, Vinh Cuu District, Dong Nai

- Hotline: 0936629323 - 0916206646 - (028)38755709

- Email: phongkd@xaydunghoabinh.com.vn