Explore Plastic Grating Flooring Panels - A Smart Solution for Sustainable Foundations

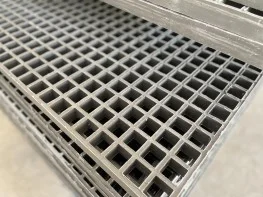

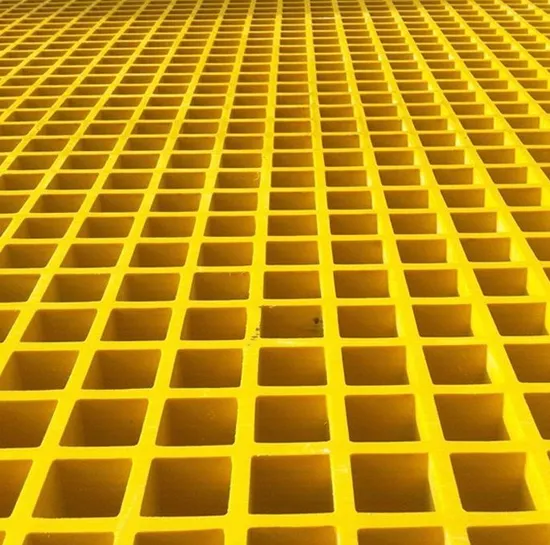

Plastic grating panels are becoming an increasingly popular choice in the construction industry due to their outstanding features and economic benefits. With good load-bearing capacity, durability, and lightweight, plastic grating panels are becoming the top choice for many modern construction projects.

Why Choose Plastic Grating Panels in Construction?

When choosing materials for construction, sustainability and cost are always top priorities. Plastic grating panels have proven their advantages in many fields.

Load-Bearing Capacity

Plastic grating panels are designed to withstand heavy loads, making them an ideal choice for industrial and commercial construction projects.

- Durable material:

These panels are typically made from composite plastics or PVC, offering high mechanical strength without being affected by weather conditions.

- Long-lasting durability: Unlike metals or wood, which are prone to rust or rot, plastic grating panels maintain their durability and functionality for many years.

Lightweight and Easy to Install

One of the biggest advantages of plastic grating panels is their lightweight, making installation much easier.

- Reduced transportation costs:

The lightweight nature of the plastic grating panels helps reduce transportation costs when delivering materials to construction sites.

- Easy to install: Installation is not only quick but also requires less labor, resulting in high economic efficiency for contractors.

Flexible Applications

Plastic grating panels are not only used in construction but also have a variety of applications in different fields.

- Piping construction and maintenance:

They are often used in drainage systems to prevent water damage.

- Industrial projects: Many factories and production facilities have chosen plastic grating panels for their factory floors due to their slip resistance and ease of cleaning.

Environmentally Friendly

In addition to technical features, plastic grating panels also align with environmental protection trends.

- Waste reduction:

The production of plastic grating panels can be done using recycled plastics, thus reducing unnecessary waste.

- Non-toxic: Plastic grating panels are completely free from harmful chemicals, ensuring safety for users and the surrounding environment.

Specific Features and Advantages of Plastic Grating Panels

To learn more about plastic grating panels, we need to explore their specific features and advantages. The variety of designs and features they offer can provide significant benefits for different projects.

Design Features

Plastic grating panels come in a variety of designs, each serving a specific purpose.

- Diverse designs: From simple to complex styles, consumers have many design options to match the architectural style of their projects.

- Different thicknesses and sizes: Depending on usage requirements, manufacturers provide plastic grating panels in various sizes and thicknesses for consumers to choose from.

Durability Over Time

Thanks to their composition and manufacturing technology, plastic grating panels are resistant to harsh environmental factors.

- Chemical resistance: These panels can resist many types of chemicals without corroding or losing quality.

- Weather resistance: Whether it's rain, sun, or storms, plastic grating panels maintain their shape and function, making them ideal for outdoor projects.

Safety and Convenience in Use

Safety is an essential factor to consider in any construction project.

- Slip resistance: The surface of plastic grating panels is often designed to be slip-resistant, reducing the risk for users when walking.

- Easy to clean: Plastic grating panels are very easy to clean. A little water and soap are enough to clean the surface.

Comparing Plastic Grating Panels with Other Materials

In construction, material selection is crucial and sometimes involves tough decisions.

Plastic Grating Panels vs. Metal Grating Panels

While metal grating panels have high rigidity and load-bearing capacity, plastic grating panels have several advantages.

- Rust reduction: One notable advantage is that plastic grating panels do not rust, while metal panels can be affected by moisture.

- Cost: Plastic grating panels are generally cheaper than metal panels, helping to save costs for contractors.

Plastic Grating Panels vs. Natural Wood

Natural wood is a traditional choice in construction but has several weaknesses.

- Water resistance: Wood tends to rot when exposed to water, whereas plastic grating panels are completely unaffected.

- Maintenance: Wood requires regular maintenance to keep it looking good and durable. In contrast, plastic grating panels require low maintenance.

Plastic Grating Panels vs. Concrete

Concrete panels are widely used in construction but have certain limitations.

- Heavy weight: Concrete is heavy, making the construction process more expensive. In contrast, plastic grating panels are lightweight and easy to install.

- Construction time: Concrete panels require longer installation time due to drying requirements. Plastic grating panels can be installed immediately.

Applications of Plastic Grating Panels in Real Projects

Plastic grating panels are not just theoretical but are widely used in practice. Here are specific applications.

In the Industrial Sector

Plastic grating panels are commonly used in manufacturing and processing plants.

- Food processing plants: The smooth, slip-resistant surface of plastic grating panels is ideal for food safety standards.

- Power plants: The ventilation and drainage systems of power plants can take advantage of this type of flooring.

Urban Construction Projects

In urban construction, plastic grating panels are also widely applied.

- Stairs and walkways: Plastic grating panels can be used for walkways in parks, schools, or recreational areas, creating safe spaces for pedestrians.

- Stadiums: At stadiums, plastic grating panels are used to create walkways for spectators and athletes, providing safety and aesthetic appeal.

Plastic grating panels also play an important role in environmental protection projects.

- Drainage systems: Using plastic grating panels in drainage systems helps improve stormwater collection efficiency without harming the environment.

- Water retention areas: Water retention systems for agricultural irrigation can also take advantage of plastic grating panels to ensure ventilation and easy maintenance.

Conclusion

Plastic grating panels have proven their position in the construction industry through many superior advantages, from load-bearing capacity, lightweight, versatility, chemical resistance, to environmental protection. With diverse applications in many fields, from industry to urban construction, this material is sure to continue dominating the market in the near future. The continuous development of manufacturing technology will also help plastic grating panels improve further, better serving the diverse needs of modern construction projects.