19x19 Composite Grating Flooring by Hoa Binh: A Solution for All Construction Projects

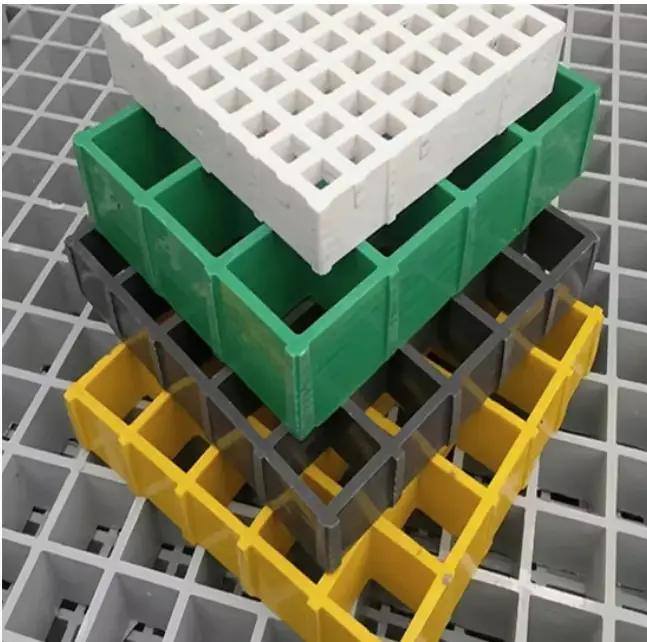

Overview of 19x19 Composite Grating Flooring

The 19x19 composite grating floor is a type of flooring made from high-quality materials such as aluminum alloy, stainless steel, or composite, with a grid structure featuring 19x19 mm square holes. This product is specifically designed to meet the requirements for strength, anti-slip properties, and efficient drainage in various environmental conditions. In this article, we will explore the concept, key features, practical applications, and the benefits that composite grating floors bring to modern construction projects.

What is 19x19 Composite Grating Flooring?

19x19 composite grating floor is a grid-style floor panel made from composite materials such as FRP (fiberglass reinforced plastic), or metals like aluminum and stainless steel, which help optimize weight and strength. This floor type meets technical standards and is also designed for safety, anti-slip properties, and ease of cleaning and maintenance.

The term "composite" in the name refers to the combination of multiple materials to form a complete product, offering superior corrosion resistance compared to traditional flooring types. In particular, the composite grating floor is adaptable to harsh environments such as industrial zones, food processing plants, outdoor projects, or underground drainage systems.

Key Features of the 19x19 Grid

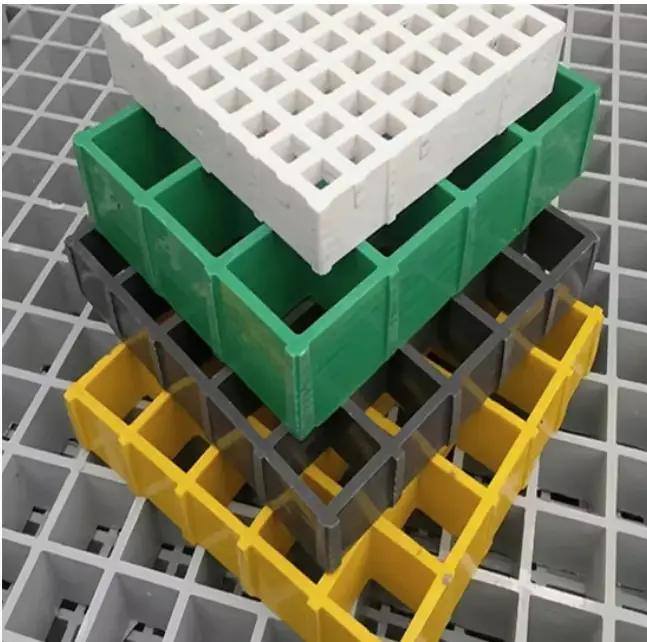

The strength of 19x19 composite grating floors lies in its regular honeycomb structure, with 19x19 mm square holes that optimize load-bearing, anti-slip properties, and fast drainage. Unlike other types of grating, the 19x19 grid strikes a balance between durability and lightweight, making it ideal for applications that require mobility or high load-bearing while minimizing overall weight.

Moreover, the 19x19 hole design minimizes dust, debris, or water accumulation on the surface, enhancing safety and environmental hygiene. This is why many contractors and investors trust composite grating floors for both large and small projects.

Common Applications in Construction Projects

With constant technological development, 19x19 composite grating flooring is becoming increasingly popular in areas such as factory construction, industrial stair systems, flooring in industrial parks, manhole covers, drainage grates, safety nets, and drainage systems. Due to its versatility, high durability, and anti-slip capabilities, this flooring type is ideal for environments that require high workplace safety standards.

Additionally, with its anti-oxidation properties and excellent heat resistance, Hoa Binh Grating is also used in fireproof systems, waterproofing, and environmental protection. In the industrial field, it serves as a durable flooring layer, supporting easy operations, repairs, and maintenance.

Benefits of Using 19x19 Composite Grating Flooring

Choosing 19x19 composite grating flooring is not only for aesthetic purposes but also offers many strategic benefits for your project. First, its superior load-bearing capacity ensures maximum safety for users, minimizing the risk of workplace accidents. Second, its lightweight design reduces the load on the entire building structure, saving on transportation and installation costs.

Moreover, the corrosion resistance and oxidation protection of FRP composite grating floors help maintain long-term durability, minimizing maintenance and replacement costs. The ease of installation, easy cleaning, and excellent anti-slip properties contribute to the overall efficiency of projects.

Components of 19x19 Composite Grating Flooring

To better understand the effectiveness of 19x19 composite grating flooring, let’s take a closer look at the components that make up this product. Each material and part plays a crucial role in its durability, load-bearing capacity, corrosion resistance, and overall safety.

Primary Materials: Aluminum Alloy, Stainless Steel, or Composite

Aluminum alloy is one of the most popular choices for manufacturing composite grating floors, due to its lightweight, easy processing, and high corrosion resistance. Aluminum also reduces the overall weight of the product, making it easier to transport and install.

Stainless steel is often used in environments that require high strength, heat resistance, and absolute corrosion protection. This material is suitable for use in areas with harsh weather conditions or direct exposure to chemicals and seawater.

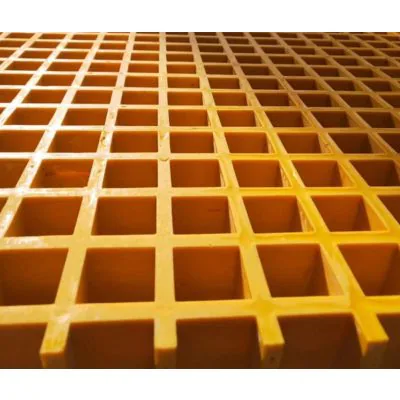

Composite is an eco-friendly material made of fiberglass-reinforced plastic (FRP). This material is lightweight, highly corrosion-resistant, and ideal for outdoor applications, maintaining stable quality over time and being resistant to deformation or cracking.

Structure and Standard Size of the 19x19 Grid

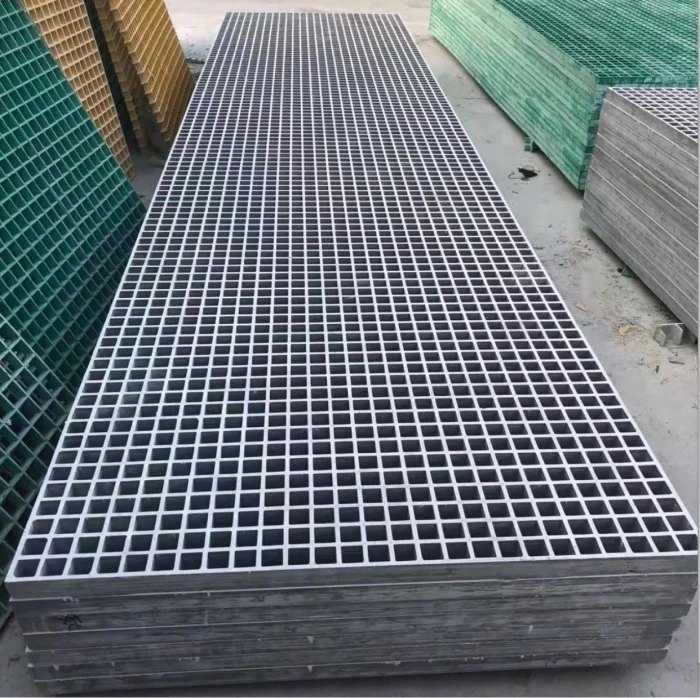

The structure of 19x19 composite grating flooring consists of steel or aluminum bars connected in a square grid pattern, with each hole measuring 19 mm in width and length. This design helps maximize uniform force distribution, minimizing the risk of breakage or deformation.

Auxiliary components, such as stainless steel or high-quality aluminum connectors, help securely fasten the panels together. These components also ensure a fast installation process, with easy removal and repair when necessary.

Auxiliary Parts and Fastening Accessories

During production and installation, auxiliary parts like screws, bolts, locks, and guide rails are made from corrosion-resistant materials, ensuring the panels are securely connected and maintaining the overall stability of the system.

These accessories also help adjust the height and level the flooring during installation, minimizing technical deviations. Using high-quality accessories extends the product's lifespan and maintains its effectiveness throughout the project’s lifecycle.

Technical Advantages of 19x19 Composite Grating Flooring

The advantages of 19x19 composite grating flooring lie in its superior technical features, making it suitable for any construction project, whether large or small. From load-bearing capabilities and corrosion resistance to safety, all of these qualities enhance the value of the product.

High Durability and Good Load-Bearing Capacity

Thanks to its solid structure and high-quality materials, this composite grating can handle significant loads, making it suitable for areas with heavy pedestrian and vehicular traffic. Its ability to withstand impacts and vibrations over time helps reduce wear and tear, enhancing safety.

It also performs well in harsh environmental conditions, resisting deformation, warping, or decay over time, maintaining stable durability even after many years of use. This is why businesses and organizations prioritize purchasing composite grating floor quotes from reputable suppliers like Hoa Binh to ensure quality.

Corrosion and Oxidation Resistance

A key criterion in choosing construction materials is corrosion resistance, especially in wet environments, marine climates, or chemically harsh conditions. FRP grating floors in general and FRP composite grating floors specifically offer superior corrosion and rust resistance compared to traditional metal floors.

This helps minimize regular maintenance costs, significantly extending product lifespan, and preserving aesthetic appearance and safety over time.

Lightweight, Easy Installation

One of the standout advantages of composite grating flooring is its lighter weight compared to traditional floors like concrete or heavy steel. This makes transportation and installation much faster, saving labor costs and reducing construction time.

The installation process is simple and does not require complex equipment, making it easier for contractors and engineers to manage timelines and ensure project progress. Additionally, the flexibility in cutting and adjusting dimensions makes it adaptable to various architectural designs.

Safety and Anti-Slip Effectiveness

With its open grid structure, composite grating flooring offers excellent drainage, reducing the risk of slippery surfaces that can pose safety hazards. The anti-slip surface design provides a strong grip, ideal for environments with moisture or grease.

This safety feature is especially crucial in public areas, factories, stairways, or industrial walkways, minimizing workplace accidents and ensuring user safety.

Practical Applications of 19x19 Composite Grating Flooring

With numerous advantages, 19x19 composite grating flooring has become a top choice for construction projects, improving operational efficiency and ensuring safety during use. Its applications are widespread and versatile, suitable for various types of projects.

In Scaffolding and Industrial Stair Systems

In construction projects, scaffolding is essential to ensure safety and convenience when working on higher floors. Composite grating floors provide sturdy, anti-slip surfaces to support assembly, maintenance, and repair activities.

In industrial stair systems, composite grating reduces weight, is easy to install, and can be removed when no longer needed. Additionally, its corrosion resistance helps maintain safety and cleanliness in chemical or dirty environments.

Used for Sidewalks and Industrial Park Flooring

In urban projects or industrial parks, using composite grating as a ground surface enhances drainage, reduces water accumulation, and prevents slip hazards or surface peeling. This flooring is ideal for areas with heavy vehicle traffic or pedestrian movement, offering high anti-slip performance.

Furthermore, due to its aesthetic appeal, granitic flooring enhances landscape value, creating a modern, clean feel for urban spaces.

Drainage Systems and Composite Manhole Covers

In drainage systems, composite manhole covers or composite grating flooring play dual roles as covers and drainage solutions, preventing blockages. Diverse models and sizes like 19x19 grids are suitable for various locations.

Composite manhole covers are also durable, anti-slip, easy to install, and perfect for projects requiring durability and aesthetic appeal. Using these products enhances environmental safety and cleanliness.

Trash Screens and Safety Grills

Trash screens and safety grills made from composite or metal materials meet safety standards, providing anti-slip, anti-corrosion properties. These are often used to protect drainage systems, preventing falls or debris from entering the sewers.

Using grating flooring helps users better understand the features and applications of these products.

Production Process of 19x19 Composite Grating Flooring at Hoa Binh

To ensure the highest quality for composite grating floors, the production process must strictly adhere to technical steps from material selection, fabrication to final quality checks. Hoa Binh is proud to possess advanced production lines that guarantee each product meets the highest standards.

Choosing the Right Materials

The production process begins with selecting high-quality materials suitable for each project. Materials such as aluminum alloy, stainless steel, or composite FRP are selected based on international standards such as ASTM and ISO, ensuring durability, corrosion resistance, and load-bearing capacity.

Choosing the right materials not only directly impacts the product's quality but also helps minimize technical errors, optimize production costs, and enhance the brand's reputation.

Precision Fabrication Process

After selecting the appropriate materials, the fabrication process involves cutting, welding, and linking the components according to the 19x19 grid standard. Advanced, automated fabrication technology ensures the panels are precisely made with even corners, without technical flaws.

Controlling temperature and pressure during welding and bonding is a key factor in determining the durability and load-bearing capacity of composite grating floors. Skilled technicians at Hoa Binh thoroughly check every detail to ensure international standards are met.

Quality Control After Production

After fabrication, each grating floor undergoes rigorous checks for dimensions, hardness, load-bearing capacity, anti-slip features, and corrosion resistance. These tests are based on international standards like ANSI, BS, and ASTM to ensure accuracy.

Only products that meet all technical standards are packed, quality insured, and sent to customers. Hoa Binh Construction Technology Production & Trading Co., Ltd. is committed to providing 19x19 composite grating floors that meet international standards, ensuring customer satisfaction and peace of mind in every project.

Technical Standards and Quality Certifications

To ensure reputation and meet customer requirements, all composite grating floors at Hoa Binh must adhere to international technical standards and possess appropriate quality certifications, demonstrating the product's reliability.

Applicable International Standards

Our products comply with international standards such as ASTM A36, ASTM A123, ISO 9001, and ISO 14001, ensuring quality, safety, corrosion resistance, and long service life. This ensures peace of mind for customers using them in projects with stringent technical requirements.

Moreover, production processes must comply with labor safety, environmental protection regulations, ensuring sustainable development and corporate social responsibility.

Quality Certification and Independent Testing

Hoa Binh’s composite grating products are certified by reputable independent organizations in the construction industry. These certifications not only help customers make informed choices but also enhance the company's reputation in both domestic and international markets.

We are committed to maintaining the highest standards in every product, from design and material selection to fabrication and final inspection. This ensures maximum peace of mind for customers investing in construction projects, from factories, industrial stairways to drainage systems, manhole covers, and other components.

Conclusion

As the construction industry increasingly demands safety, sustainability, and efficiency, 19x19 composite grating floors have proven their position as an optimal solution, suitable for many types of projects. From load-bearing capacity, corrosion resistance, lightweight design to ease of installation, the technical features of this flooring contribute to improving work efficiency, minimizing risks, and saving costs for businesses. Hoa Binh Construction Technology Production & Trading Co., Ltd. is proud to be a leading supplier of high-quality composite grating floors, particularly 19x19 composite grating floors, committed to providing complete customer satisfaction and peace of mind through every project. With an experienced technical team, modern production systems, and international certifications, we aim to con

Completed Projects orther

- Manhole Covers Installed in Tra Vinh - Trash Guards Installed in Tra Vinh

- Manhole Covers Installed in Tuyen Quang – Trash Guards Installed in Tuyen Quang

- Manhole Covers Installed in Vinh Phuc – Trash Guards Installed in Vinh Phuc

- Manhole Cover in Yen Bai – Trash Guard Installed in Yen Bai

- Manhole Covers and Trash Guards Installed in 63 Provinces

- Manhole Cover Project Exported to Cambodia - Trash Guard Exported to Cambodia