FRP Composite Grating Floor Panels - Manufactured by Hoa Binh Group

The FRP composite grating flooring is gradually becoming the top choice in industrial, civil construction, and infrastructure projects due to its outstanding advantages in durability, lightweight, corrosion resistance, and diverse applications. With the development of new materials, this flooring not only effectively replaces traditional steel grating but also opens up the trend of using composite materials in many high-technical standard fields.

Overview of FRP Composite Grating Flooring

FRP composite grating flooring offers a perfect alternative to metal floors, which are prone to corrosion and degradation under various environmental conditions. Before diving into the advantages and applications of this product, let's explore its structure, basic properties, and why more businesses are choosing it for their projects.

Structure and Components of FRP Composite Grating Flooring

https://xaydunghoabinh.com.vn/san-pham/san-grating-composite

FRP composite grating flooring is primarily composed of fiberglass (Fiberglass) combined with high-quality polyester or vinylester resin, produced through a modern molding process.

The fiberglass serves as reinforcement, increasing the load-bearing capacity and enhancing the mechanical stability of the product. Meanwhile, the composite resin base protects the fiberglass from environmental impacts while providing water resistance, chemical resistance, and UV resistance.

The combination of these two components makes the flooring significantly lighter than steel, while still offering high durability, good elasticity, and a long service life.

Additionally, depending on the usage requirements, the FRP composite grating flooring can be designed with various mesh hole patterns to allow drainage, reduce weight, or increase slip resistance by adding a rough surface coating.

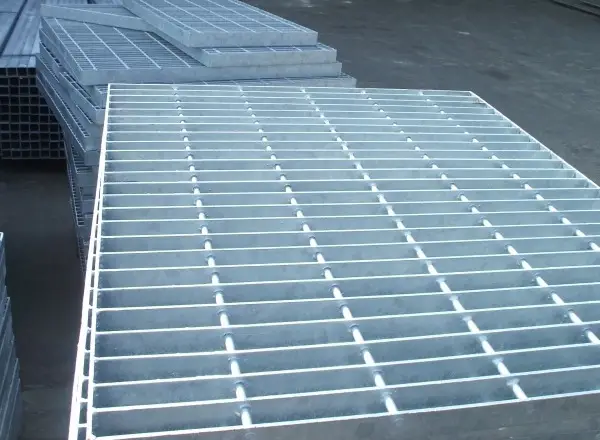

Outstanding Advantages Compared to Traditional Gratings

One of the biggest advantages of FRP composite grating flooring is its near-perfect resistance to corrosion in environments involving acids, alkalis, seawater, and chemical solvents.

On the other hand, steel grating, even when galvanized or coated, still suffers from rust over time, especially when exposed to moist environments or chemicals. This leads to higher maintenance costs, replacements, and safety concerns.

Moreover, thanks to its weight being only about 1/3 to 1/4 of steel, transporting and installing FRP composite grating flooring is much easier, saving on labor costs and installation time.

Additionally, composite materials are electrically insulating, have low heat conductivity, and contribute to safety in explosive or electrically demanding environments.

Why Choose FRP Composite Grating Flooring

It can be said that FRP composite grating flooring combines the qualities of "durability, lightweight, safety, and cost-effectiveness" to become the optimal flooring solution for modern projects.

By eliminating the issues caused by rust, businesses can significantly reduce long-term maintenance costs while maintaining the initial appearance and safety for users.

The product also improves labor efficiency, reduces the load on the overall structure of the project thanks to its lightweight, thus enabling more creative and flexible design options compared to traditional materials.

Top 3 Outstanding Advantages of FRP Composite Grating Flooring

Not just a simple replacement for steel grating, FRP composite grating flooring has several outstanding advantages that make it an ideal choice in a variety of real-world applications. Below is a detailed analysis of the most prominent benefits of this new material.

Mechanical Durability and Long Service Life

The load-bearing capacity of FRP composite grating flooring is impressive, thanks to the fiberglass woven inside the resin base layer.

The product can withstand loads equivalent to or even exceeding those of traditional steel grating, while maintaining a lightweight profile, thus reducing the overall load on the structure of the project.

Furthermore, composite materials are less affected by weather factors such as temperature, humidity, or UV radiation, helping maintain mechanical durability even after years of outdoor or harsh environmental use.

According to practical studies, the average lifespan of FRP composite grating flooring can reach 30-50 years without the need for painting or complicated maintenance, far surpassing conventional metal grating.

Therefore, investing in this type of flooring brings long-term economic benefits, minimizing repair and replacement costs throughout its service life.

Excellent Corrosion Resistance and Chemical Resistance

One of the standout features of FRP composite grating flooring is its near-perfect corrosion resistance under harsh working conditions.

The composite material can withstand the effects of seawater, acids, alkalis, oils, and organic solvents without diminishing its mechanical properties or deforming the surface.

This makes it an ideal choice for chemical plants, oil refineries, food processing plants, wastewater treatment systems, and coastal projects or oil rigs.

Thanks to its excellent chemical resistance, the flooring is also less susceptible to rotting and does not require frequent protective coating, significantly reducing the overall operating costs of the system.

Moreover, FRP composite material is non-magnetic, making it suitable for environments that require strict electromagnetic field control, such as laboratories and radar stations.

Lightweight, Easy to Install and Maintain

Weighing only about 1/3 of steel, FRP composite grating flooring is highly convenient for transportation, installation, and dismantling.

The installation process does not require specialized lifting equipment, which reduces labor costs and accelerates construction progress.

Additionally, due to its modular design, replacing individual tiles in case of damage is very flexible, without the need to dismantle the entire flooring system.

The composite surface also helps reduce dust buildup, making it easy to clean or wash, meeting the strict hygiene requirements of industries such as food, medical, or clean industries.

The stability of the material further helps reduce shrinkage or thermal expansion, minimizing cracks and warping during prolonged use.

Safety for People and Environmentally Friendly

Another important advantage of FRP composite grating flooring is its electrical insulation, which ensures safety for workers in explosive environments or areas requiring high electrical insulation.

Moreover, FRP composite materials have a high melting point, good fire resistance, and some types are added with flame retardant additives to ensure fire safety.

The production process of this material generates minimal harmful waste, is recyclable, or can be disposed of easily after its service life, contributing to reducing environmental impacts.

The material is free from heavy metals or hazardous compounds, does not pollute water or air under normal usage conditions, and complies with international safety standards and sustainable development trends.

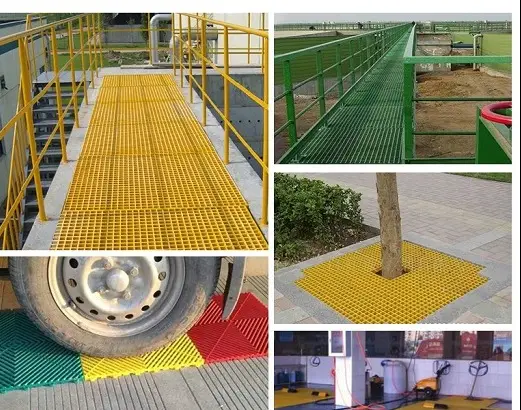

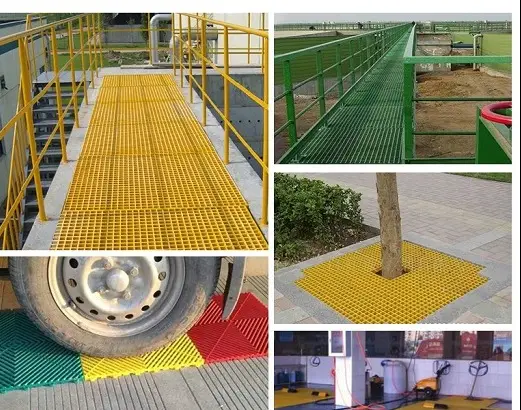

Common Applications of FRP Composite Grating Flooring in Practice

Thanks to its many outstanding advantages, FRP composite grating flooring is increasingly being applied in various industries and fields. It not only effectively replaces metal flooring but also expands its range of applications due to its exceptional properties.

Chemical, Oil & Gas, and Water Treatment Industries

In chemical plants, oil refineries, or wastewater treatment systems, the working conditions are very harsh with frequent exposure to corrosive chemicals and toxic solvents.

Using FRP composite grating flooring ensures high safety and long service life for work platforms, technical walkways, and equipment supports.

The product resists corrosion from acids, alkalis, seawater, or organic solvents, helping the system operate stably and reducing maintenance costs.

Additionally, its electrical insulation and non-flammability help increase workplace safety in areas prone to explosions or electrical leakage.

Especially, its lightweight helps reduce the load on offshore platform structures, where weight plays a critical role in design and operation.

Food, Pharmaceutical, and Clean Industries

In food and pharmaceutical production plants, strict hygiene and contamination control are paramount.

FRP composite grating flooring, with its smooth surface that reduces dust buildup, is easy to clean, and does not rust or corrode, making it the ideal choice.

Its excellent corrosion resistance ensures that the flooring is not affected by strong cleaning and disinfecting solutions, extending its lifespan and reducing replacement frequency.

Additionally, since the composite material contains no heavy metals or toxic substances, it guarantees absolute safety during product processing and packaging.

The clean production environment, free of rust dust, also helps improve product quality and meet the strict food safety standards.

Transportation Infrastructure, Civil Works, and Public Systems

Not only confined to the industrial sector, FRP composite grating flooring is also widely used in civil works and urban infrastructure projects.

Pedestrian bridges, elevated technical walkways, guardrails, and emergency stairways can all use this material to reduce the load on the structure while still ensuring strength and stability.

The corrosion resistance ensures that the flooring remains colorfast and does not rust, even when installed outdoors, along coastlines, or in humid climates.

The anti-slip surface and ease of cleaning enhance safety, reducing accidents caused by slipping in public areas.

Moreover, the high aesthetic appeal, diverse color options, and ease of shaping make FRP composite grating flooring an attractive material for interior and exterior decoration.

Special Applications: Shipbuilding, Electronics, and Special Projects

In the shipbuilding industry, FRP composite grating flooring is widely used on deck, outdoor work platforms, and storage compartments, thanks to its ability to resist seawater and corrosion.

The electronics industry uses its electrical insulation and non-magnetic properties to install it in laboratories and factories that manufacture components sensitive to electromagnetic fields.

Other special applications include emergency systems, military engineering floors, radar stations, airports, and substations, where FRP composite flooring is prioritized due to its superior features.

As we can see, the scope of application for this material is expanding, contributing to enhancing quality, safety, and reducing operating costs across various industries.

Important Considerations When Choosing and Installing FRP Composite Grating Flooring

Despite having many outstanding advantages, to maximize its effectiveness, businesses need to pay attention to several technical factors when selecting, designing, and installing FRP composite grating flooring.

Accurate Load and Size Requirements

The first important factor when choosing a flooring type is accurately determining the load that the floor needs to bear, including both static and dynamic loads.

Based on these specifications, the supplier will recommend the most suitable type of fiberglass, mesh density, thickness, and weave pattern.

Choosing the right materials ensures operational safety and prevents waste when using a floor that exceeds actual requirements.

Additionally, the floor's size, shape (square, rectangular, circular), and edge design must align with the installation space and intended use.

It’s important to ensure that joints and connections are precise to ensure a secure fit, preventing sinking or shaking during installation and long-term use.

Choosing the Right Resin Base and Surface Style for the Environment

Next, selecting the appropriate resin base for the composite is also crucial.

If the work environment is highly acidic or alkaline, vinylester resin should be preferred over regular polyester to enhance chemical resistance.

For high-temperature or fire-risk environments, a resin with flame-retardant additives should be chosen to meet fire safety standards.

For the surface, depending on the need for anti-slip or ease of cleaning, options like rough coatings, serrated patterns, or glossy resin coatings can be selected for aesthetics.

Choosing correctly will extend the product's lifespan and ensure maximum safety for users in real-world conditions.

Proper Training for Installation and Execution

Another important consideration is ensuring that the installation team is properly trained in handling composite materials to ensure high-quality installation.

Techniques such as cutting, drilling, and bolting should use specialized tools to avoid damaging the internal reinforcing fibers.

Securing the flooring to steel or concrete frames should use appropriate accessories to prevent cracking at anchor points.

Also, avoid moving or dropping the flooring from heights to ensure that the internal structure remains undamaged and that the flooring retains its longevity and safety.

Following the correct installation procedure will maximize the effectiveness of the flooring and minimize risks during later maintenance and operation.

Regular Maintenance and Cleaning to Maintain Durability

While FRP composite grating flooring is highly durable and corrosion-resistant, regular cleaning and maintenance are essential for long-term performance.

Check joints and fixation points regularly to identify any damage or cracks early.

Surface cleaning can be done easily with clean water, soap, or mild cleaning solutions, avoiding strong chemicals that may degrade the resin base.

If cracks are found, contact the supplier for repair or replacement options to ensure safety during further use.

Frequently Asked Questions About FRP Composite Grating Flooring

Can FRP composite grating flooring completely replace steel grating?

Absolutely. With many advantages, including corrosion resistance, lightweight, electrical insulation, and high mechanical durability, FRP composite grating flooring is gradually replacing steel grating in many applications, especially in chemical environments, coastal areas, or where electrical insulation is required.

What is the average lifespan of FRP composite grating flooring?

The average lifespan of this flooring can range from 30 to 50 years, depending on environmental conditions and usage intensity. This is significantly higher than conventional steel floors.

Does FRP composite grating flooring require regular maintenance?

No complex maintenance is required. Just periodic cleaning and checking for damage at the joints. If any damage is found, repairs or replacements should be done, saving maintenance costs compared to steel.

Is FRP composite grating flooring suitable for outdoor use?

Yes, it is ideal. Thanks to its UV resistance, corrosion resistance, and weatherproof properties, this product is perfect for use on pedestrian bridges, outdoor walkways, guardrails, and decks without worrying about rusting or color fading.

Is the cost of FRP composite grating flooring higher than steel?

The initial cost may be slightly higher than steel, but considering the total lifecycle cost (long lifespan, low maintenance, easy installation), using FRP composite grating flooring will save significantly in the long run.

Conclusion

In the trend of sustainable development and improving construction quality, FRP composite grating flooring stands out as the optimal choice thanks to its superior advantages: durability, lightweight, corrosion resistance, electrical insulation, safety, and versatility.

Investing in this advanced material not only improves operational efficiency and reduces maintenance costs but also contributes to ensuring environmental safety and worker health. We hope this article has provided a comprehensive overview to help you choose the most suitable flooring solution for your projects.

IV. Contact Information

-

https://www.youtube.com/@Nap-ho-ga-song-thu-rac-Grating

-

Hotline: 0936629323

Completed Projects orther

- Manhole Covers Installed in Tra Vinh - Trash Guards Installed in Tra Vinh

- Manhole Covers Installed in Tuyen Quang – Trash Guards Installed in Tuyen Quang

- Manhole Covers Installed in Vinh Phuc – Trash Guards Installed in Vinh Phuc

- Manhole Cover in Yen Bai – Trash Guard Installed in Yen Bai

- Manhole Covers and Trash Guards Installed in 63 Provinces

- Manhole Cover Project Exported to Cambodia - Trash Guard Exported to Cambodia