Best steel replacement lah: Composite Grating Floor, strong and light one

In Singapore, industries and commercial projects often face challenges with traditional steel grating floors – they’re heavy, prone to corrosion, and costly to maintain. That’s why Composite Grating Floor is gaining popularity as the best steel replacement: lightweight, robust, and corrosion-resistant. This article explains why Composite Grating is ideal, where to use it, its advantages, and how to choose the right supplier.

1. Understanding Composite Grating Floor

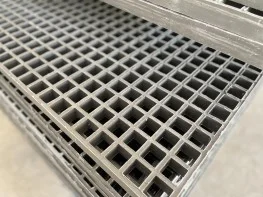

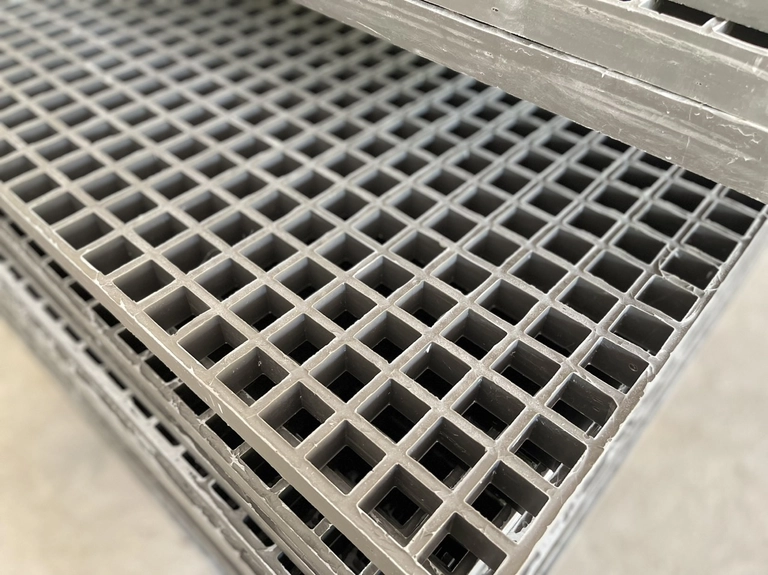

Composite Grating Floor is a structural floor panel made from fiber-reinforced plastic (FRP) combined with high-performance resin. The composite material gives it outstanding strength, durability, and lightweight properties, making it a superior alternative to traditional steel grating.

Key properties:

-

Lightweight – easier to handle and install.

-

High tensile strength – withstands heavy loads, industrial machinery, and pedestrian traffic.

-

Corrosion-resistant – suitable for chemical plants, marine environments, and humid climates.

-

Non-slip surface – enhances safety for workers and the public.

-

Low maintenance – no rust, repainting, or protective coatings needed.

2. Advantages of Composite Grating Floor

2.1 Lightweight Design

Unlike steel grating, Composite Grating is easy to transport, handle, and install. One or two workers can install a panel without heavy machinery. This reduces labour cost and installation time significantly.

2.2 Exceptional Strength

Despite its light weight, Composite Grating supports heavy loads, including forklifts or industrial equipment. Its high tensile strength ensures it performs reliably under demanding conditions.

2.3 Corrosion and Chemical Resistance

Singapore’s tropical climate and coastal areas can accelerate steel corrosion. Composite Grating is immune to rust, moisture, and chemical exposure, ensuring long-term durability.

2.4 Safety Features

The non-slip surface reduces accident risks in wet or industrial environments. This makes Composite Grating ideal for walkways, platforms, and public spaces.

2.5 Longevity and Low Maintenance

With a lifespan of 15–20 years, Composite Grating requires minimal maintenance, reducing overall operational costs compared to steel alternatives.

3. Applications in Singapore

Composite Grating is versatile and can be applied in:

-

Industrial facilities – mezzanine floors, platforms, and walkways.

-

Marine environments – piers, docks, and coastal structures.

-

Chemical and processing plants – resistant to corrosive liquids.

-

Commercial projects – public walkways, shopping centers, and rooftop platforms.

-

Residential and public areas – safe, durable, and visually appealing flooring solutions.

4. Design Options and Specifications

Composite Grating panels are available in multiple sizes, thicknesses, and colors to suit different applications.

-

Panel sizes: Standard 1220 x 2440 mm, custom sizes available.

-

Thickness options: 25 mm, 38 mm, 50 mm depending on load requirements.

-

Colors: Grey, yellow, black, green, and custom colors to match design aesthetics.

-

Surface finishes: Smooth, anti-slip, or serrated for additional safety.

5. Cost Comparison: Steel vs Composite Grating

| Material | Cost per m² | Maintenance | Lifespan |

|---|---|---|---|

| Steel Grating | Higher | Repainting & rust repair | 5–10 years |

| Composite Grating | Moderate | Minimal | 15–20 years |

While initial investment may be slightly higher than steel, long-term savings on maintenance, installation, and safety costs make Composite Grating a cost-effective solution.

6. Installation Guidelines

Proper installation ensures performance and longevity:

-

Load Assessment – Select panel thickness according to expected load.

-

Support Framework – Use steel or FRP support frames for structural stability.

-

Fastening – Use stainless steel screws or bolts; avoid nails.

-

Cutting & Drilling – Precision tools prevent chipping and maintain structural integrity.

-

Regular Inspections – Check for wear or damage after heavy usage.

7. Choosing a Reliable Supplier in Singapore

To maximize benefits, select a supplier who:

-

Provides high-quality FRP material with UV protection.

-

Offers certified load testing and technical specifications.

-

Has proven track record with industrial, commercial, or marine projects.

-

Supports custom design options – size, color, surface type.

-

Offers warranty and after-sales service for peace of mind.

8. Conclusion

For Singapore industries, commercial projects, and public facilities, Composite Grating Floor is the ideal steel replacement:

-

Strong yet lightweight

-

Corrosion-resistant and safe

-

Low maintenance with long lifespan

-

Versatile for multiple applications

Switching to Composite Grating not only reduces costs but also enhances safety and efficiency. It’s the smart, professional choice for modern flooring solutions.

9. Call to Action

Contact a trusted Composite Grating supplier in Singapore today. Request product samples, quotes, and technical support to ensure your project benefits from the strongest, safest, and most cost-effective flooring solution available. Don’t wait – upgrade your floor system with Composite Grating now!

Dự án đã thực hiện khác

- Komposittgitter – Fremtiden for byggeindustrien

- Трендови во употребата на композитни решетки за подови во модерната градба

- Komposiittimateriaalien käyttö rannikkoalueiden rakennushankkeissa

- Miért fektetnek egyre több vállalkozás a kompozit anyagokba?

- Παγκόσμιες τάσεις της αγοράς για τα δάπεδα σύνθετων σχαρών

- Efterspørgslen efter kompositristegulve i Nordamerika og Europa

- Нови технологии при производството на FRP композитни решетъчни плочи