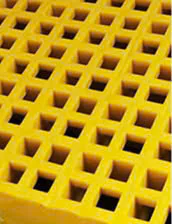

Composite Grating Floor with One Closed Anti-Slip Surface 1220x2440

Composite grating floor with a non-slip solid surface is one of the optimal solutions to ensure safety for outdoor work areas, industrial zones, or places that require high durability and anti-slip capabilities. This product not only helps reduce the risk of slipping but also provides aesthetics, superior durability, and resistance to harsh weather conditions.

In this article, we will explore in detail this special type of flooring – from its structural characteristics, practical applications, to its outstanding benefits, as well as how to choose the right one to ensure maximum efficiency in your projects.

Overview of Composite Grating Floor with One Non-Slip Solid Surface

The composite grating floor with one non-slip solid surface is a type of flooring made from composite materials combined with a special design to create a sealed surface that is anti-slip and suitable for use in environments requiring high safety standards. The product's standout feature is its excellent resistance to weather, chemicals, impacts, and long-term use while maintaining its original properties.

Before diving into further analysis, it's important to understand that this type of flooring is popular in industries, construction, factories, overpasses, or elevated walkways, where anti-slip standards and durability are paramount to ensure the safety of workers and users.

Structure of the composite grating floor with one non-slip solid surface

The composite grating floor typically consists of two main parts: the sealed surface layer and the anti-slip surface layer. The sealed surface helps prevent dirt, water, or other liquids from penetrating, keeping the floor clean and reducing the risk of slipping due to oil or water accumulation. The anti-slip surface can include textured patterns, raised grooves, or special coatings to increase friction and reduce the risk of slipping.

Structure and Operating Principle of the Composite Grating Floor with One Non-Slip Solid Surface

Understanding the structure and operating principle of composite grating floors helps managers and technicians easily select, install, and operate them correctly, while optimizing their performance.

Main Components of Composite Grating Floor

- Main Material: Typically composite from fiberglass or fiberglass-reinforced plastic, providing high durability, lightweight, and corrosion resistance.

- Sealed Surface Layer: Usually made of epoxy resin or polymer surface coatings, designed to prevent water, dirt, and oil from penetrating.

- Anti-Slip Surface Layer: It can include textured patterns, raised grooves, or special non-slip coatings, depending on the intended use.

Operating Principle of the Composite Grating Floor with One Non-Slip Solid Surface

The product operates by increasing friction between the floor surface and the feet of users or moving equipment. The sealed surface helps maintain cleanliness, while the anti-slip layer ensures that all activities are carried out safely, even when the surface is wet or oily.

Benefits of Composite Structure in Practice

Composite materials offer excellent resistance to corrosion and oxidation, making them suitable for harsh environments such as marine, chemical exposure, or high temperatures. Furthermore, their lightweight nature ensures easier transportation and installation compared to traditional metal or concrete floors.

Outstanding Benefits of Composite Grating Floor with One Non-Slip Solid Surface in Practical Applications

Choosing the composite grating floor with one non-slip solid surface provides many outstanding benefits, particularly well-suited for the increasing demand for safety, economic efficiency, and sustainability in industry. These features help improve work productivity, minimize accident risks, and optimize maintenance costs.

Absolute Safety in Work Environments

Anti-slip is a crucial factor in areas with wet floors, oils, or those prone to slipping, such as food processing plants, chemical factories, and elevated construction sites. The sealed surface helps prevent liquids from leaking below, keeping the area clean and minimizing slip-and-fall accidents.

Ability to Withstand Harsh Weather Conditions

The composite grating floor performs well under all climatic conditions, including rain, intense heat, or freezing temperatures. With its anti-slip coating and corrosion-resistant materials, this product is not affected by oxidation, rust, or fading over time.

Cost-Effective Investment and Maintenance

These floors have a long lifespan, require little maintenance or replacement, reducing operational and maintenance costs. Additionally, the lightweight nature helps reduce transportation and installation costs, as well as lighten the load on foundation structures.

Versatile Applications in Various Fields

- Factories, warehouses

- Overpasses, public walkways

- Electric, gas, chemical areas

- Drainage systems, cooling systems, waste treatment plants

Classification of Products Suitable for Different Purposes

Composite grating floors can be customized in size, coating, and design to suit specific applications, thus optimizing their usage efficiency and maintaining safety standards.

Process of Selecting and Installing Composite Grating Floor with One Non-Slip Solid Surface Effectively

Choosing the right floor type and ensuring proper installation techniques are essential factors determining the effectiveness and durability of the product during use.

Criteria for Choosing the Right Composite Grating Floor

- Identify installation location and environmental conditions

- Assess the required anti-slip level

- Determine the appropriate size and shape for the space

- Choose materials based on durability, chemical, and temperature resistance

Preparation Steps Before Installation

- Survey the current site conditions and foundation structure

- Prepare the necessary materials and check product quality

- Plan the construction process with clear steps

Composite Grating Floor Installation Process

- Prepare the stable, clean surface

- Install steel frames or fixed frames if needed

- Place the composite floor in the designated position, secure it firmly

- Check for flatness and safety, ensuring no sharp edges

- Complete and inspect, then put into use

Post-Installation Notes

- Check periodically for signs of wear or damage

- Clean the surface regularly to maintain anti-slip features

- Follow the manufacturer’s maintenance instructions

Trends and New Technologies in Composite Grating Floor Production

With the advancing technology era, composite grating floors are continuously improving in design, material, and applications. These trends open up new opportunities for businesses and investors looking to explore optimal, innovative, and sustainable solutions.

Development of Advanced Composite Materials

- Applying new materials such as carbon fiber, high-temperature resistant plastics, and eco-friendly materials

- Enhancing resistance to harsh climatic conditions, chemicals, and strong impacts

- Reducing weight while ensuring optimal stiffness and durability

Smart Anti-Slip Coating Technology

- Using nano-coatings, textured tiles, and complex raised patterns to optimize anti-slip performance

- Developing self-healing coatings to prevent scratches, extending product lifespan

- Using 3D printing technology to create unique design patterns suited to specific projects

Green and Sustainable Technology Applications

- Manufacturing according to eco-friendly standards to minimize harmful emissions

- Utilizing recycled materials to reduce construction waste

- Designing integrated drainage systems and dust control to reduce environmental pollution

Global Market Potential and Development

- The demand for anti-slip composite flooring is increasing in developed countries

- High-rise construction projects, overpasses, and urban roads are prioritizing these products

- Expanding into regions with harsh climates and chemical environments

FAQ - Frequently Asked Questions About Composite Grating Floor with One Non-Slip Solid Surface

What materials are commonly used to manufacture composite grating floors?

The products are typically made from fiberglass, fiberglass-reinforced plastics, or other high-quality composite materials suitable for environmental resistance.

https://sangrating.vn/san-pham/san-grating-composite

How can I ensure the floor remains non-slip effectively?

Choose the appropriate anti-slip coating, design raised grooves or textured patterns on the surface, and regularly clean and maintain the floor to preserve its anti-slip features.

Is composite grating floor suitable for underwater environments?

Yes, composite materials are resistant to water and corrosion, making them ideal for areas in direct contact with water or high humidity.

What is the average lifespan of a composite grating floor?

The average lifespan is between 10-20 years, depending on the usage conditions, maintenance, and the quality of the initial product.

Can the size and design of the floor be customized?

Yes, most suppliers offer customization services to meet the specific requirements of each project.

https://www.youtube.com/watch?v=Lcw7duYJIvY

## Conclusion

We have explored the composite grating floor with one non-slip solid surface – an optimal solution in terms of safety, aesthetics, and durability for various applications in industry and construction. Thanks to its special structure, high anti-slip performance, and excellent resistance to harsh weather conditions, this product has become the preferred choice for project managers. Choosing the right type of floor not only ensures worker safety but also enhances operational efficiency and reduces long-term maintenance costs. As technology continues to advance, new research and innovations are opening up more opportunities for these products to become even more refined, contributing to the sustainable growth of the construction and infrastructure industries in the future.

Hoa Binh Construction Technology Manufacturing & Trading Co., Ltd

Specializing in the production of COMPOSITE GRATING FLOORING - COMPOSITE MANHOLE COVERS - COMPOSITE DRAINAGE BARRIERS nationwide.- Address: 69 Tan Lap, Tan Lap Ward, Dong Hoa District, Di An City, Binh Duong, Vietnam

- Hotline: 0942.001.001

- Email: info@fdola.com

Products orther

FRP Composite Grating Floor Panel 1220 x 2440 x 50

Composite Grating 1220x2440 with 19x19 Hole Size

Slip-Resistant Sand-Coated Composite Grating 1220x2440x38

FRP Composite Grating Sheet 1220 x 2440 x 30

FRP Composite Grating Sheet 1220 x 2440 x 20