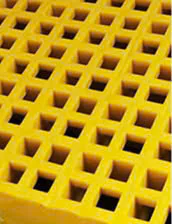

Slip-Resistant Sand-Coated Composite Grating 1220x2440x38

In industrial, construction, or slippery-risk areas, the safety of workers and visitors is always a top priority. Composite grating flooring has become a popular solution due to its ability to provide excellent traction, high durability, and easy installation. This article will help you better understand the concept, the best products available today, as well as provide criteria for choosing the right option to ensure maximum safety.

Definition and Importance of Anti-slip Composite Grating Flooring

What is Anti-slip Composite Grating Flooring?

Anti-slip composite grating flooring is a type of grating floor made from composite materials (a mix of plastic, alloys, or synthetic materials) with a grid or parallel bar design to reduce slipping and increase traction for users. This type of flooring is commonly used in wet areas, places with a high risk of slipping, such as factories, elevator stairs, balconies, warehouses, or docks and piers.

Why is Anti-slip Composite Grating Flooring Necessary?

- Maximum safety: Minimizes the risk of falls and injuries in areas with water or oil.

- Good load resistance: High durability, suitable for high-load areas.

- Easy maintenance and cleaning: Easy to clean, rust-resistant, and keeps clean for a long time.

- High aesthetics: Modern design, suitable for various architectural styles.

- Cost-effective: Long lifespan, low replacement frequency, easy installation, and transportation.

Common Types of Anti-slip Composite Grating Flooring

Below is a list of the 5 best anti-slip composite grating products based on price, features, user feedback, and reliability.

| Product Name | Main Material | Key Features | Price | Average Rating | Main Applications |

|---|---|---|---|---|---|

| FRP Composite Grating | FRP (Fiberglass Composite) | Chemical resistant, lightweight, effective anti-slip | Medium | 4.7/5 | Factories, stairs, chemical tanks |

| Rubber Composite Grating | Alloy combined with synthetic rubber | Extremely high slip resistance, noise reduction | High | 4.6/5 | Wet areas, food processing plants |

| Metal Composite Grating | Aluminum, stainless steel coated with composite | High load resistance, durable | High | 4.8/5 | Heavy load areas, ramps, factory walkways |

| PVC Composite Grating | PVC plastic | Easy installation, low cost, good anti-slip | Low | 4.5/5 | Small industrial areas, gardens, hallways |

| Premium Anti-slip Composite Grating | Special composite materials | Optimized for safety, high durability | Very high | 4.9/5 | High-standard environments like clean rooms, hospitals |

Criteria for Choosing the Right Anti-slip Composite Grating Flooring

Material

Choose the material suitable for the environment: FRP, rubber alloys, aluminum, or PVC depending on requirements for durability, chemical resistance, or weight.

Slip Resistance

Consider the product's slip resistance based on environmental conditions (wet, oily, slippery areas).

Load Resistance

Determine the maximum load the floor needs to withstand in order to select the appropriate material and avoid damage or deformation.

Size and Design

Choose the appropriate size for the installation space while ensuring easy installation and maintenance.

Price and Budget

Balance between quality and cost to select a product that fits the project's budget.

Steps to Properly Install Anti-slip Composite Grating Flooring

Prepare the Ground

- Clean dust, oil, and check the flatness of the surface.

- Measure the exact location for installation.

Select Suitable Materials

- Based on the technical requirements that have been defined.

Installation Process

- Place the grating panels in the correct position and align them properly.

- Use screws, clamps, or special adhesives to secure them.

- Check the stability and firmness of the grating after installation.

Regular Cleaning and Maintenance

- Clean regularly to maintain slip resistance.

- Check the fasteners and repair any issues promptly.

Tips for Common Issues

- If the grating is loose, tighten the screws or clamps.

- If scratched or damaged, replace the affected section to ensure safety.

Comparison of Common Anti-slip Composite Grating Flooring Types

Below is a comparison table of the key features of each type:

| Product Type | Main Material | Key Features | Average Price | Weight | Main Applications |

|---|---|---|---|---|---|

| FRP Composite | Fiberglass, fiberglass threads | Lightweight, good chemical resistance | Medium | Light | Factories, storage tanks, stairs |

| Synthetic Rubber | Rubber + metal | Excellent slip resistance | High | Medium | Wet areas, processing plants |

| Metal Coated Composite | Aluminum, stainless steel | Good load resistance, high durability | Very high | Heavy | Heavy load areas, ramps |

| PVC Plastic | PVC plastic | Low cost, easy installation | Low | Light | Small industrial areas, gardens |

| Special Materials | Premium composite | Maximum safety, high durability | Very high | Medium | Special environments, medical |

Video

Conclusion

Anti-slip composite grating flooring is the optimal solution for environments requiring high safety, excellent slip resistance, and long-lasting durability. Choosing the right type based on material, slip resistance, load capacity, and budget will help ensure safety for users and enhance the operational efficiency of the project. To achieve maximum performance, attention should be given to the installation process and regular maintenance to prolong the lifespan and maintain the anti-slip functionality of the product.

HOA BINH CONSTRUCTION TECHNOLOGY MANUFACTURING & TRADING CO., LTD

Specializing in the production of COMPOSITE GRATING FLOORS - COMPOSITE MANHOLE COVERS - COMPOSITE DEBRIS GUARDS nationwide.

- Address: 69 Tan Lap, Tan Lap Village, Dong Hoa Ward, Di An City, Binh Duong, Vietnam

- Main Factory: 68 Tan Hien Street, Thien Tan Commune, Vinh Cuu District, Dong Nai

- Hotline: 0936629323 - 0916206646 - (028)38755709

- Email: phongkd@xaydunghoabinh.com.vn

- Business Registration Certificate No. 3703055512, managed by Di An City Tax Department, issued on 28/04/2022

OUR BRANCHES

- HCMC Representative Office: 702 Hanoi Highway, Hiep Phu Ward, Thu Duc City, HCMC

- Da Nang Representative Office: 68 Ly Nhan Tong, Khuê Trung Ward, Cam Le District, Da Nang

- Hanoi Representative Office: 70 Nguyen Duc Canh, Tan Mai, Hoang Mai, Hanoi

- Binh Duong Representative Office - Production Unit 1: 69 Tan Lap, Dong Hoa Ward, Di An City, Binh Duong

- Production Factory 2: No. 12, Group 7, Quang Trung Ward, Thai Nguyen City

- Production Factory 3: Sao Vang Industrial Complex, Tho Xuan District, Thanh Hoa

Products orther

FRP Composite Grating Floor Panel 1220 x 2440 x 50

Composite Grating 1220x2440 with 19x19 Hole Size

Composite Grating Floor with One Closed Anti-Slip Surface 1220x2440

FRP Composite Grating Sheet 1220 x 2440 x 30

FRP Composite Grating Sheet 1220 x 2440 x 20